Current refractory dryout procedures are NOT scientifically based – and in most cases are excessively long and very expensive.

Our P-Drying® software creates refractory dryout schedules that are:

- Tailor made for your vessel or pre-cast shape

- Uses process gas. No expensive equipment needed.

- The correct procedure during weld stress relief

- Reduces risk of refractory failure

We have helped our customers reduce their dryout times by 50%. This can translate into days saved in lost production.

Customers Include:

How it works

Our software allows us to simulate the scientific mechanisms during refractory dryout

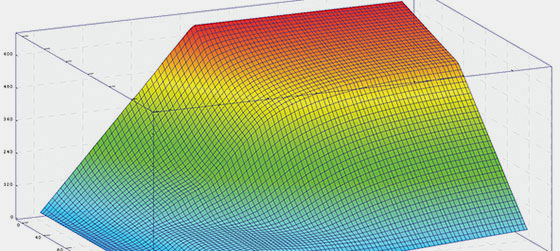

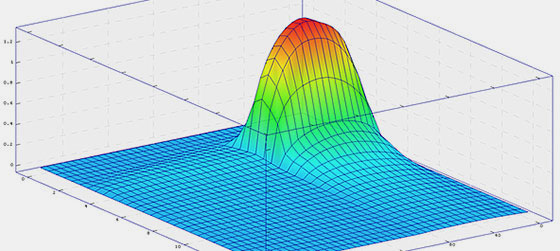

1. Vapour pressure development during drying

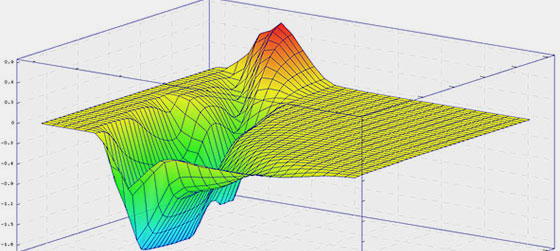

2. Water flow (flux)

3. Heating curve