Acid Plants

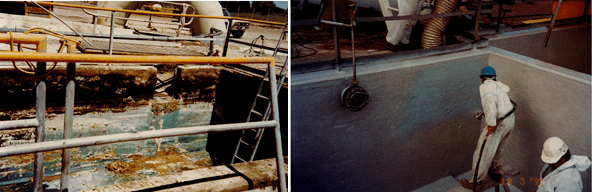

The production of sulphuric and phosphoric acids are very hazardous processes and the protection of steel vessels from corrosion, erosion and high temperatures requires refractory and process knowledge and continual maintenance.

The performance of acid-resistant bricks and membranes in these industries is a key challenge to achieving greater relatability and reducing maintenance costs. Quality workmanship can be difficult in such corrosive environments however it is essential to achieve reliable outcomes. Additionally, time constraints for maintenance shutdowns require performance and problem solving under pressure from condition assessment to implementation of repairs.

Our Services

Lining Designs

Shutdown Support

Our professional material and process engineers can independently assess the refractory repair scope required to meet reliability goals and ensure unnecessary repairs are avoided. We can generate ‘on the spot’ technical solutions that account for site material limitations and provide technical solutions to emergent problems within the resource constraints of the shutdown. Additionally, we provide future work scopes for the next shutdown.

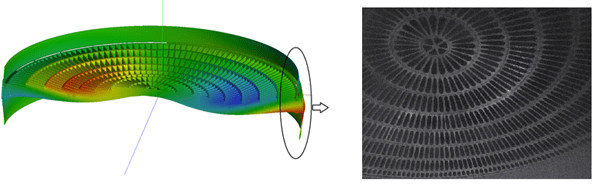

Failure Analysis

When acid linings show signs of degradation, i.e., cracks, it is very important that any assessment/investigation correctly identifies the underlying mechanism and its condition. Our expertise in material assessment/analysis to extends to development of effective testing regimes, and interpretation that translates to real-world improvements. In combination with our computer simulation & modelling capabilities, we have helped clients correctly identify the root causes, failure criteria and provided simple solutions.

Concrete Assessment & Repairs

We specialise in the assessment of concrete structures degraded by corrosion, chemical attack, thermal stress, weathering. We undertake assessment of your structures, identify key failure mechanisms, and carry out repairs. Our experts are familiar with silos, stacks, sulphur pits, effluent tanks, plinths, columns, and other structures.

Our Clients

Case Studies

Failures cost money

We’ve helped dozens of industry leaders save money by thinking ahead. Come and join the success stories.

Get in Contact